One of the largest suppliers of envelopes in Australasia, just acquired a Winkler + Dünnebier 102 machine completely rebuilt and upgraded by Curtius Technologies Inc.

The machine was tested at Curtius headquarters in Atlanta, at almost 1200 envelopes per minute, in the presence of renowned envelope manufacturers. This major milestone positions Curtius as the only truly independent alternative in the envelope industry.

Easy and cost-effective operation

The reconstructed W+D 102 was fitted with a new motor, AC drive and 4 upgraded electrical boxes attached directly to the main sections of the machine, for a fast and easy installation. No cumbersome on site rewiring needed during installation.

Two new touch screens located in the window cutting section and in the delivery section allow operators to centrally control all functions of the machine including: regulating the temperature of the Infrared drying system, changing batch parameters and options, controlling the speed of the machine or locating and trouble-shooting in real-time paper jams to minimize machine downtime.

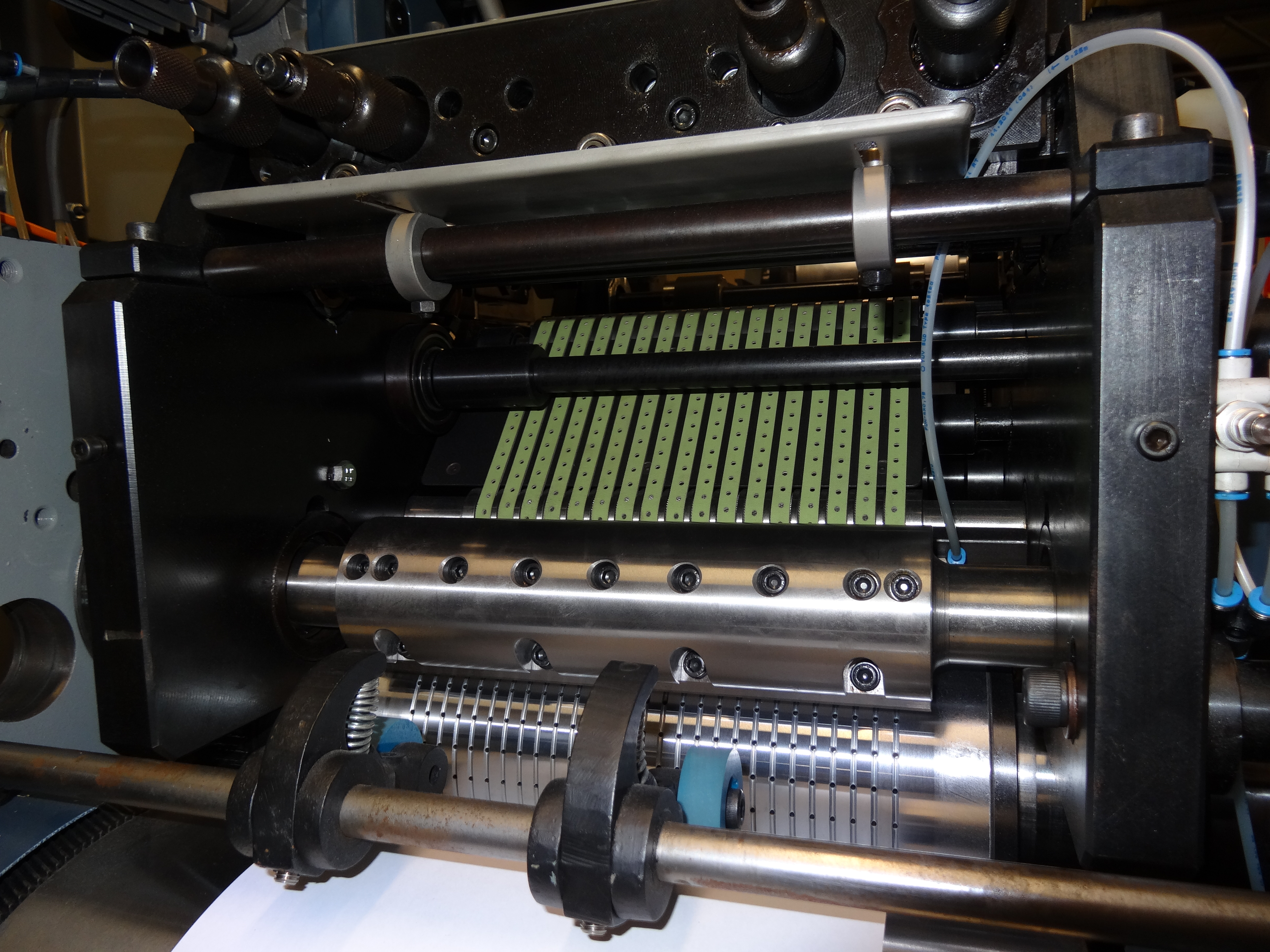

The new Panel Cutter (PC) is fully automated. This new system deactivates the PC when the machine is stopping and engages the PC and the patch automatically once the machine reaches a predetermined speed, allowing the operator to start the machine from any location.

A tension control system continuously adjusts the tension on the web with the use of two-servo motors, thus preventing the web from breaking and saving time and money.

Improved production throughput

The machine is retro-fitted with a new high-speed patcher, which applies the glue onto the window film instead of the paper at speeds up to 1200 epm, thus reducing significantly the risk of glue projections and costly paper jams. The improved patcher unit also allows the use of window film thinner than 30 micron for a much more cost-effective and eco-friendly operation than traditional patchers.

The new efficient Infrared Drying Technology used on the W+D 102 directly targets the glue deposited on the envelope-closing-flap instead of the surrounding air or paper, which improves the overall envelope-drying time and reduces significantly the energy consumption of the machine (from 60 kW to 12 kW) for a more cost-effective and eco-friendly operation.

Reduce maintenance cost and set up time

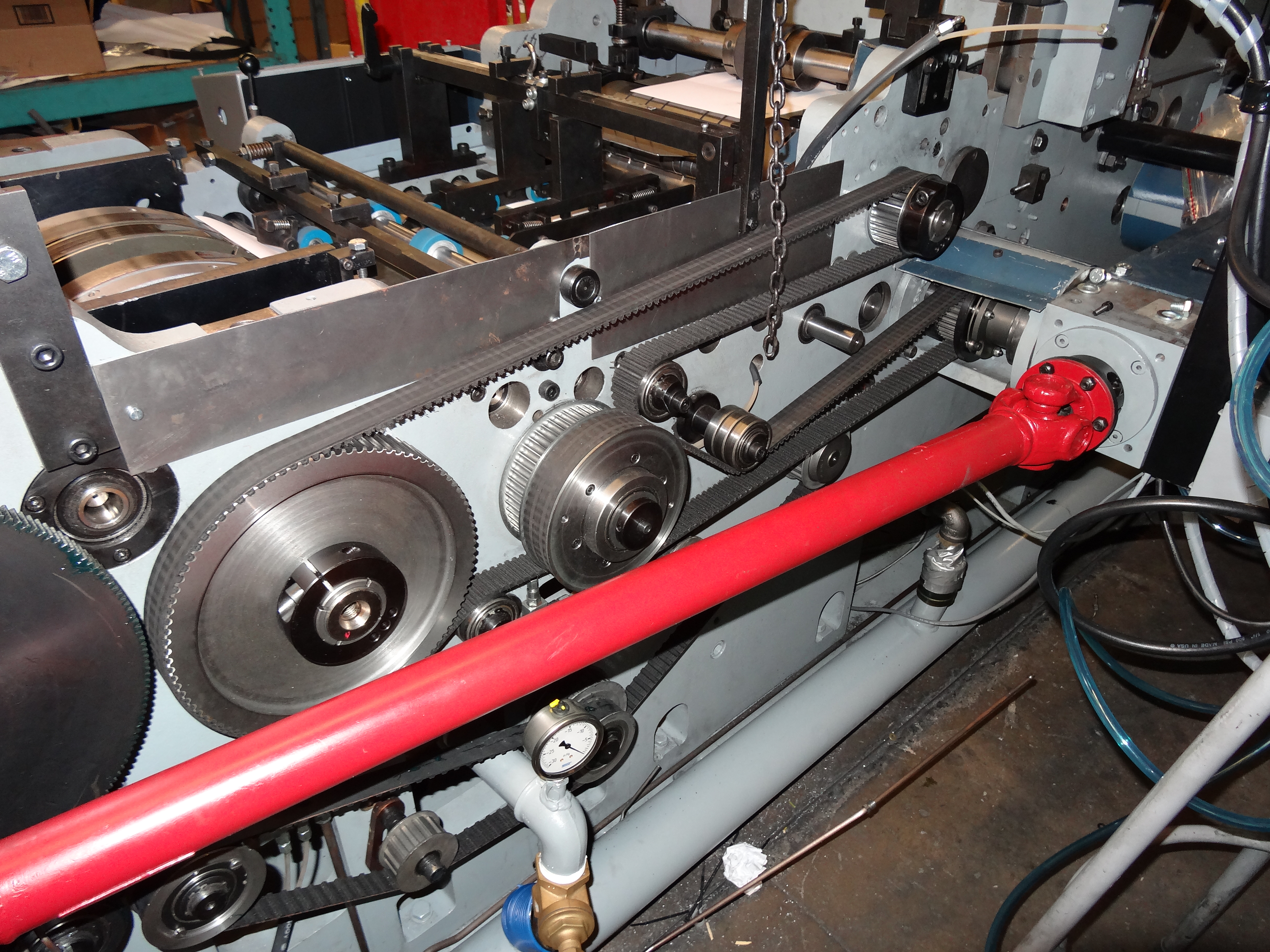

A new upgraded belt transmission system coupled with harmonic drive gearing is installed throughout the machine (in the scoring, separating, staggering as well as delivery sections), which allows “on-the-run” adjustment, reducing set up time and maintenance costs.

The result is a fully reconstructed and upgraded W+D 102 that exceeds original specifications at a fraction of the cost of new equipment. So if you are looking for additional machines, upgrades, refurbishment, or just help in an ever more difficult market place, Curtius can deliver.

For more information on reconstructed and upgraded envelope-making and envelope-printing machines or to discuss your specific envelope needs, visit www.curtius.com