Are you planning on starting or expanding your envelope business but want to keep the cost-of-ownership of your envelope equipment down? If so, take a look at re-manufactured and upgraded pre-owned envelope-making machines. They can meet or exceed original design and performance specifications of new equipment at a fraction of the cost, thus sharpening your company’s competitive edge.

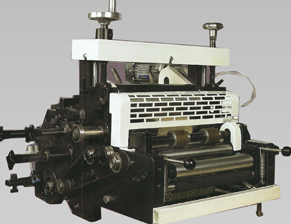

So what exactly is a fully reconstructed and upgraded envelope-making machine? For the sake of the argument, I have chosen to describe a W+D 102, a reel-fed envelope machine fully reconstructed and upgraded by Curtius Technologies.

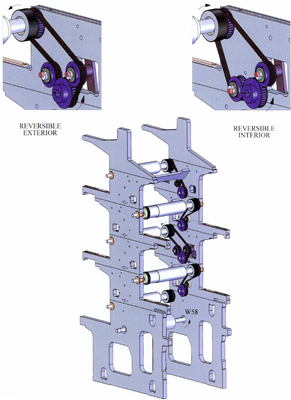

The first step of the re-manufacturing process includes stripping down the original W+D 102 envelope-making machine to replace all wear and tear parts (rubber rolls, belts, chains, busing, bearing…), rewire it and install a new electrical box. A new upgraded belt transmission system is also installed throughout the machine and in particular in the Printing unit, as shown below. This boosts the overall performance of the equipment and lowers maintenance costs thanks to more readily available spare parts.

The machine is then fitted with new technology, enhancements and upgrades designed and engineered by Curtius Technologies and its partners. On the W+D 102 such upgrades include for example the installation of a high-speed window patcher –that will immediately increase the maximum speed as well as upgrades such as doctor blade system, which guarantees a sharper printing quality even at high speed.

The result? An envelope-making machine like “New”, which can run up to 1000 envelopes per minute, is easier to install –no cumbersome onsite rewiring needed and operates smoothly and cost-effectively.

For more information on reconstructed and upgraded envelope-making machines or to discuss your specific envelope needs, visit www.curtius.com